Having built a 4×8 “traditional” construction slot car table (which must weigh over 100 pounds), I have decided there must be a better way to go about constructing a track. Some search of the usual forums led to discussions of routing a track in XPS foam. This is the dense pink or blue foam (depending on which hardware store you go to).

I did some experiments with cutting a slot in this material. I tried a few different bits in my rotary tool, and while this worked, the remaining surface wasn’t great. The material wanted to tear and ball instead of cut.

I did some testing with a few different hot wire cutters, and decided the simplest solution was to just put a custom tip in a soldering iron and use that to burn the slot in. The burned in slot has nice smooth surfaces, with a bit of a hard “face” to them.

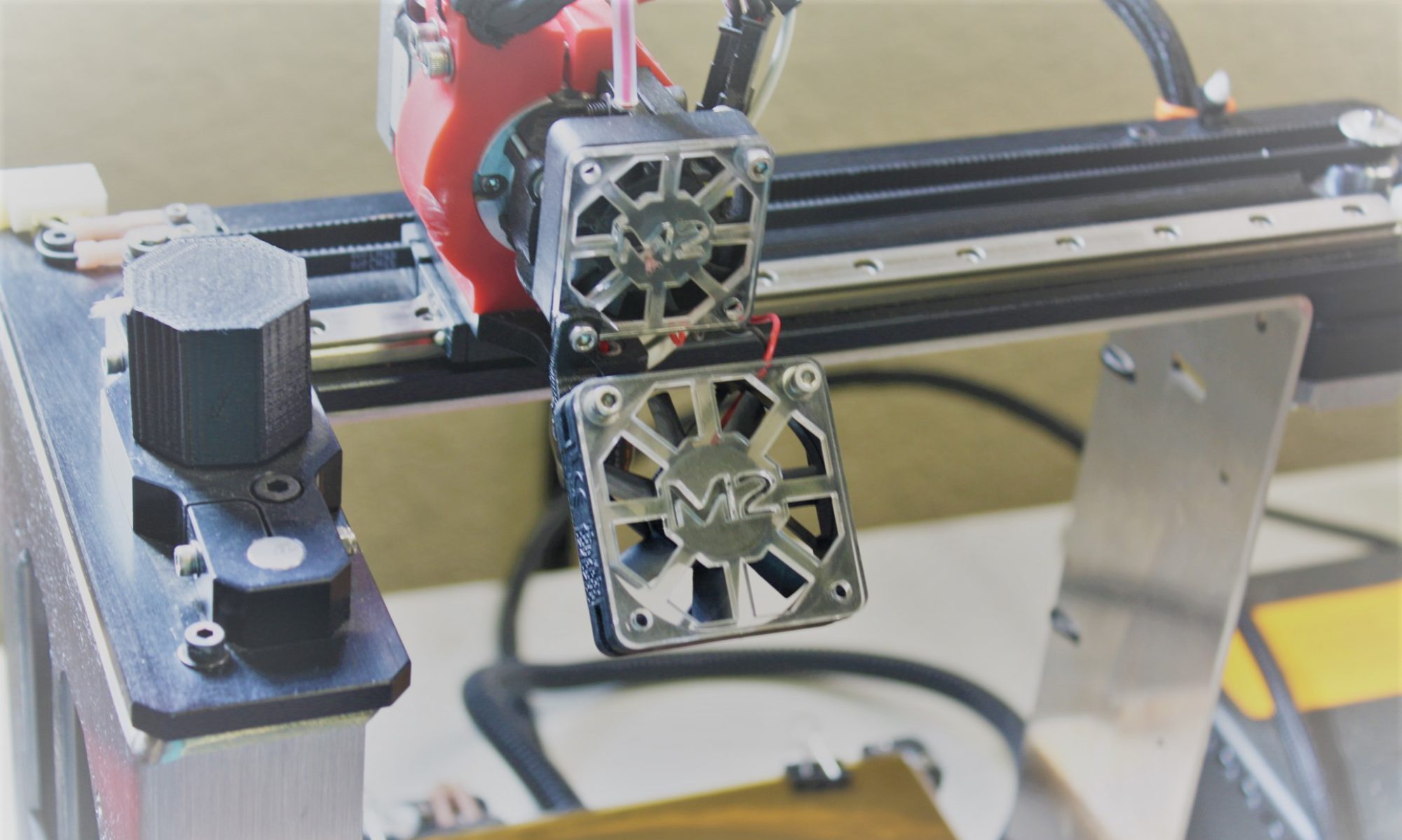

To make this process manageable, I designed a fixture to hold the iron perpendicular to the track surface. The whole fixture is 3D printed, and in the end looks a lot like a router.